发布时间:2022-08-25

来源:

2022金砖国家工业创新大赛

入围决赛项目信息

一、参赛项目名称(中文)

干式切削润滑技术与装置

二、参赛项目名称(英文)

Dry Lubrication Technology and Device Design

三、参赛单位(中文)

中北大学

四、参赛单位(英文)

North University of China

五、项目简介(中文)

实现2030年前碳达峰、2060年前碳中和的目标,既是中国做出的郑重承诺,更是目前中国紧锣密鼓推进的重点工作。实现“双碳”目标,将成为地方政府和企业发展的硬约束,也给机械制造行业带来了新的机遇与挑战。

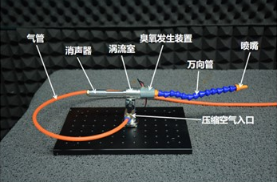

本项目将涡流冷却和静电润滑相结合,通过同一装置实现加工过程中的制冷和润滑,达到既提高加工质量又不造成环境污染的目的。项目的主要研究内容包括:在分析干式切削润滑的机理基础上,设计一款兼有静电润滑与涡流冷却的干式切削润滑结构,通过仿真研究结构参数对系统放电性能、臭氧浓度以及冷却效果的影响规律,经过结构优化设计后,进行切削试验验证所提出的干式切削润滑技术的有效性。

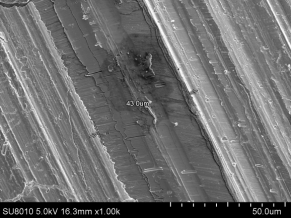

该技术目前已经过第一阶段原理样机和切削效果试验,验证了干式切削润滑技术的有效性,目前正在设计内冷润滑刀柄结构,以期进一步提升干式切削润滑效果。干式切削润滑技术经测试通过推广后,可以部分或全部取代切削液进行干式冷却润滑,降低了企业的生产成本,还可以提升生产效率与环保效益。

六、项目简介(英文)

Achieving the goals of carbon peaking by 2030 and carbon neutrality by 2060 is not only a solemn commitment made by China, but also key research that China is currently working on.Achieving the ‘dual carbongoals’ will become a hard constraint for the development of local governments and enterprises, and it will also bring new opportunities and challenges to the machinery manufacturing industry.

This project combines eddy current cooling and electrostatic lubrication to achieve refrigeration and lubrication during processing by the same device, so as to improve processing quality without causing environmental pollution.The main research contents of the project include: on the basis of analyzing the mechanism of dry cutting lubrication, design a dry cutting lubrication structure with both electrostatic lubrication and eddy current cooling, and study the structural parameters through simulation on the discharge performance, ozone concentration and cooling effect of the system. After the structural optimization design, manufacturing experiments were carried out to verify the effectiveness of the proposed dry cutting lubrication technology.

The technology has already passed the first-stage principle prototype and cutting effect test, which has verified the effectiveness of the dry lubrication technology. Currently, the internal cooling lubrication tool holder structure is being designed to further improve the dry cutting lubrication effect.After the dry cutting lubrication technology has been tested and passed the promotion, it can partially or completely replace the cutting fluid for dry cooling and lubrication, which reduces the production cost of enterprises, and can also improve production efficiency and environmental protection benefits.

七、展示图片

干式切削润滑结构图

干式切屑微观结构

八、金砖元素

项目主体单位中北大学目前与金砖国家中的俄罗斯国立科技大学(Russian Technological University )建立了学生交流中心与中俄创新合作中心;与印度的印度威尔科技大学 (Vel Tech Dr.RR &Dr.SR Technical University )进行了学生、教师交流互访,其中一人参与到该项目的研究过程中。

电话:010-68200638 、010-68207966

邮箱:biandq@cietc.org.cn 、 songxm@cietc.org.cn

联系地址:福建省厦门市思明区领事馆路1号银领中心A栋9层