Current Location:Green Industry Ecology > Comprehensive utilization of battery resources > Service guarantee >

Service guarantee

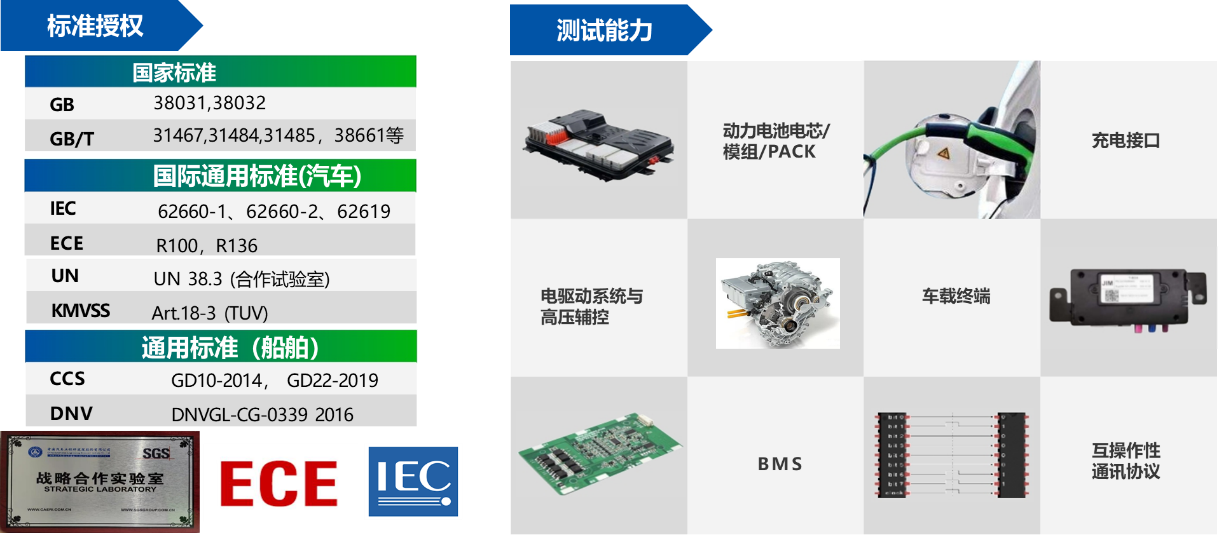

1. The battery section has complete testing capabilities for automotive power batteries and energy storage batteries. The testing objects cover individual battery cells, modules, and system level testing. The testing projects basically cover performance testing, safety performance testing, environmental performance testing, and electrical performance testing, meeting the requirements of previous regulatory inspections and enterprise DV/PV testing.

2. In terms of standard revision, due to our testing capabilities covering different levels of batteries and battery systems, electric drives and high-voltage accessories, charging interfaces and various vehicle terminals, BMS and interoperability communication protocols, we have basically completed the full coverage of common national standards and national promotion standards for such products, and have obtained corresponding authorization in international standards such as IEC/ECE/UN. At the same time, battery products have also obtained relevant qualifications from classification societies.

3. Characteristic evaluation ability

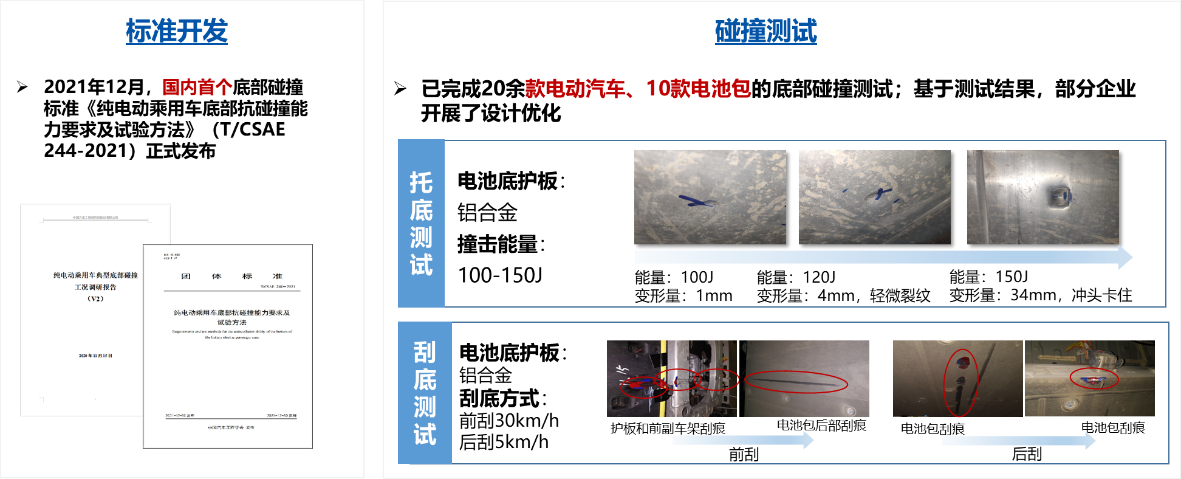

Bottom collision test: A distinctive evaluation capability developed in 2021, which took over a year to complete bottom collision tests on more than 20 vehicles and 10 battery packs, effectively evaluating the impact of new energy vehicles on battery packs under bumping and scraping conditions.

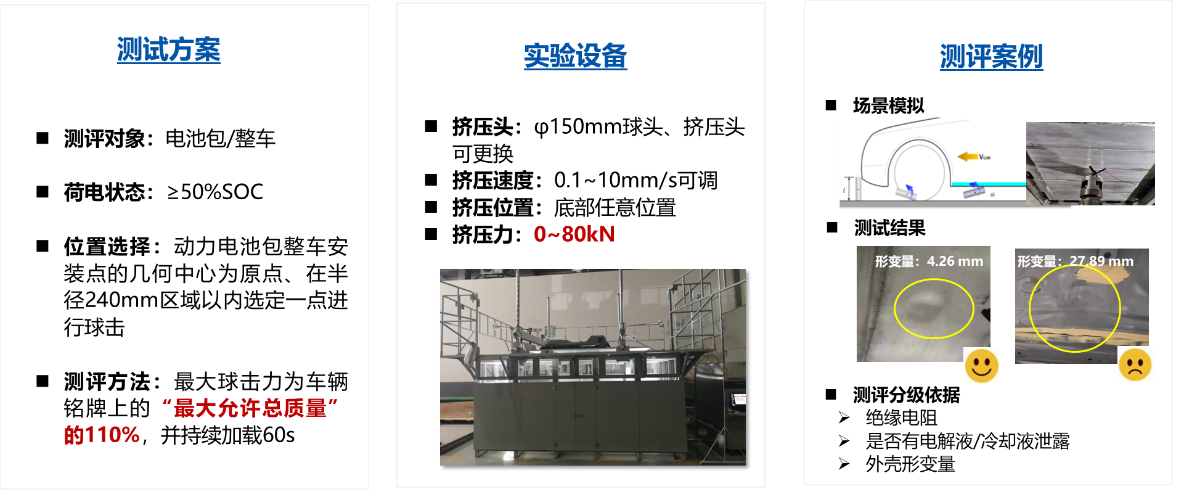

Ball Impact Test: The bottom ball impact is different from the bottom collision. The bottom collision is a dynamic impact, and the bottom ball impact is a reproduction of the quasi-static anti-collision scene at the bottom of the battery to evaluate the quasi-static anti-collision performance of the battery bottom. In this evaluation research, the first bottom ball impact test bench in China was developed, and currently, the equipment on the market basically adopts our design.

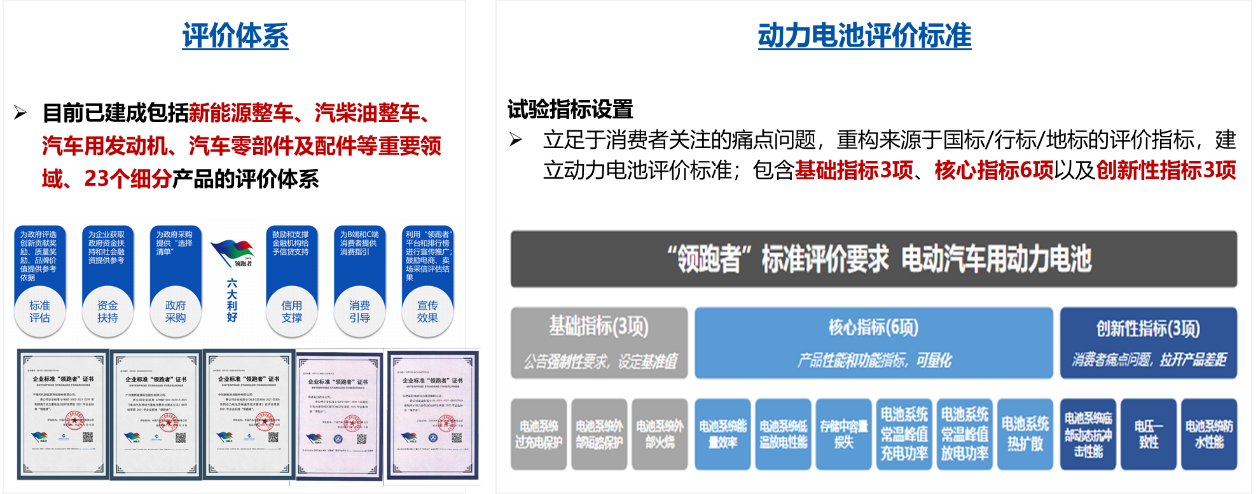

Enterprise Standard "Leader": Guiding Vehicle and Component Enterprises to Optimize and Upgrade Products

Gas production analysis: The thermal runaway gas production of power batteries is a unique evaluation capability we have developed based on UL9540A. Currently, we have completed the capacity construction at the cell level and 3MW module level, and are currently conducting laboratory construction at the 10MW system level and installation level, which can quantitatively evaluate the gas composition during the thermal runaway process of power batteries and the diffusion phenomenon of battery thermal runaway. At the individual level, the battery experiences thermal runaway in an 82L constant volume combustion bomb. The collected gas components are quantitatively analyzed through Agilent 8890GC, which can further study and analyze the combustion and explosion characteristics of the thermal runaway gas components in explosion limit testers and combustion rate testers.

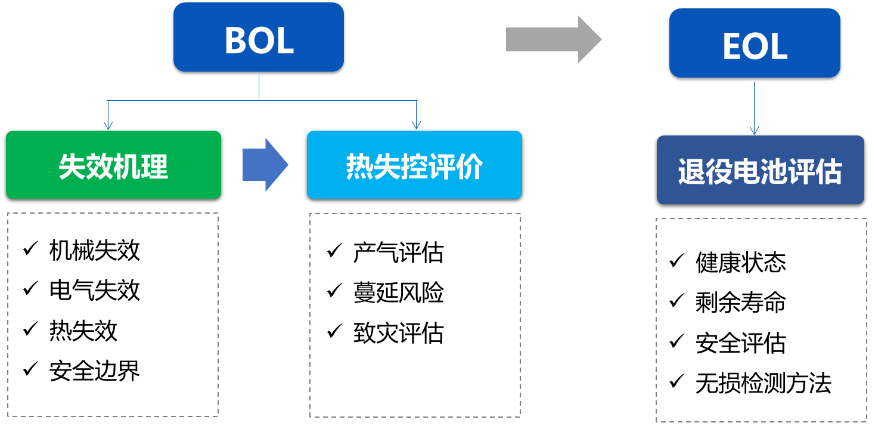

Safety evaluation system: Equipped with multi physical fields and multi-level power battery simulation technology, we have built a simulation capability for the entire vehicle thermal runaway combustion chain. We have conducted testing and evaluation system construction and safety standards around "failure mechanism research of power batteries", "safety research of thermal runaway", and "evaluation of retired batteries".

Telephone:010-68200638 、010-68207966

Email:biandq@cietc.org.cn 、 songxm@cietc.org.cn

Address:9th floor, building a, Yinling center, No. 1, consulate Road, Siming District, Xiamen, Fujian